High-End D Type Keg Coupler Handbook – Home Brew Essentials

A complete keg, or half-barrel keg, holds about 15.5 units of beer. This amounts to approximately 165 twelve-ounce measures. This significant volume underscores the requirement for adequate dispensing equipment for quality draft beer. If you are committed to brewing or initiating your home pub, knowing the D type keg coupler is essential.

In the craft beer boom, picking the best keg dispenser is vital for your brew’s freshness and flavor. Both home brewers and pub owners realize that a premium keg coupler transforms the beer serving game. This guide will cover the key gear for top-notch draft beer service, noting places like Installation Parts Supply for a selection of D type keg coupler.

Core Messages

- A full-size keg holds approximately 165 twelve-ounce servings of beer.

- The proper keg coupler is critical for safeguarding beer excellence.

- Selecting high-quality gear improves the draft beer enjoyment.

- Craft beer’s demand has risen the need for home brewing accessories.

- Keg couplers can be obtained from reputable suppliers for consistent performance.

Primer to Draft Beer Systems

The craft beer revolution has revolutionized home brewing. Enthusiasts favoring unique brews have increased the demand for specialized draft beer systems. These arrangements are crucial for keeping the beer’s taste and integrity intact. They are critical for those passionately involved in their brewing pursuits.

The Surge of Craft Beer in Home Brewing

In recent years, craft beer has surged in popularity throughout the United States. This upswing is propelled by local breweries’ creative profiles and styles. As aficionados seek to replicate these sensations at home, many are embracing home brewing. With top-tier draft beer systems, they can reach bar-quality excellence, elevating their home brewing projects.

Why Choose Draft Beer Over Bottled?

Draft beer systems offer advantages that bottles cannot. They are a byword for fresh taste and superior palate. When maintained at ideal conditions, such as 38°F, and with clean lines, these systems sustain beer integrity incomparably. Routine maintenance plays a crucial role in sustaining the draft beer’s superior taste.

Within commercial venues, draft systems demonstrate value. Selling a 15-gallon keg, delivering approximately 124 servings, can significantly boost revenue. At $3 per pint, this amounts to $372 from a single keg. This cost-effective benefit, coupled with providing exceptional craft beer, renders draft systems superior over bottles.

D Type Keg Coupler Summary

Across North America, the D type keg coupler is vital to drawing from kegs efficiently. It’s tailored for Sankey D kegs, establishing it as the premier option for beers like Budweiser, Coors Light, and Miller Lite. Understanding its architecture and its operation is vital for optimal operation, whether in business environments or for homebrew enthusiasts.

Defining a D Type Keg Coupler?

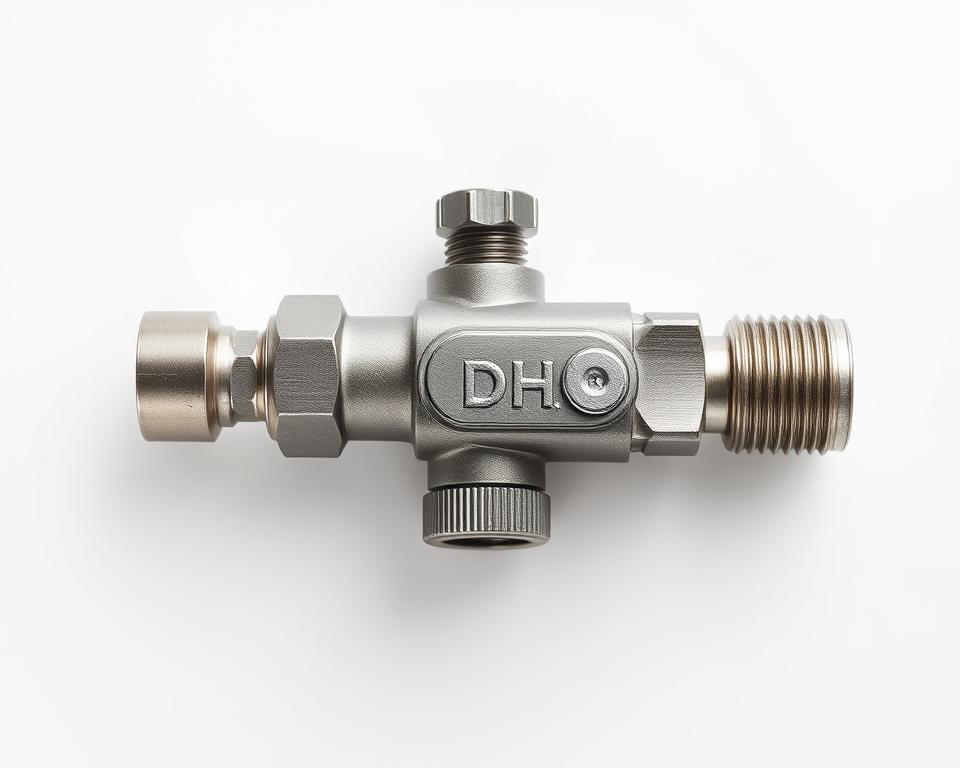

Alternatively called the American Sankey coupler, the D type connects to US Sankey faucet valves. It’s fundamental in dispensing a broad spectrum of North American beers. Constructed of nickel-plated brass and a stainless steel sensor, it features durability and anti-corrosion qualities. Its size, 5 inches tall and 4 inches wide, suit it well for kegs from Michelob, Busch, and Labatt.

Operation of the D Type Keg Coupler

The mechanism of the D type keg coupler is straightforward yet efficient. A 5/16″ I.D. gas hose connects to the entry, conveying CO2 into the keg. This generates the pressure needed to drive beer through the system. An built-in safety feature prevents surplus pressure, enhancing safety drastically. Due to its metal wing handle, it’s tougher than versions with plastic levers, serving both home and business users dependably.

Picking the Appropriate D Type Keg Coupler

Choosing the right D type keg coupler is essential for beer dispensing success. It’s imperative to evaluate a number of criteria to confirm you make an informed choice. The right equipment will not only maintain your beer’s integrity intact but also offer lasting performance and durability.

Factors to Consider When Selecting

While selecting a D type keg coupler, reflect on these critical aspects:

- Performance: It must be suited for leading brands, including Coors and Budweiser.

- Dimensions and Clearance: Opt for a low-profile design if you’re limited by space.

- Ease of Use: Select a coupler that features a intuitive lock-down mechanism.

Compatibility with Different Keg Types

Verifying your coupler matches different keg types is key for optimal results. Typically, D type couplers are suited for popular North American brews. Examples include Molson, Corona, and Yuengling fit this coupler. It’s also crucial to know other keg types, like U-type or S-type, to avoid complications during pouring.

Longevity and Material Quality

The composition of your beer delivery apparatus greatly influences its durability. Stainless steel is often chosen for its anti-corrosion and easy maintenance. For instance, the Taprite D Style Keg Coupler boasts a sturdy stainless steel body. This boosts its longevity, especially in regular use. Additionally, having access to spare parts can save you from full complete substitutions.

Advantages of Using a D Type Keg Coupler

The D type keg coupler is beneficial for commercial and home brewers alike. It enhances the draft beer system, guaranteeing beer remains high-quality. By safeguarding beer quality and simplifying installation, it is a premier choice.

Preserving Beer Quality and Crispness

Notable for beer preservation, the D type keg coupler minimizes oxidation and maintains carbonation. This retains the beer’s newness and taste, akin to mass-produced options. Labels such as Budweiser and Corona employ D-type couplers, demonstrating their importance in maintaining flavor.

Simple Installation and Upkeep

The ease of mounting a D type keg coupler is remarkable. It delivers hassle-free setup, appealing to both experts and newcomers. Maintenance is equally straightforward, making sure the system remains in prime condition without difficulty.

Enhanced Draft Performance

A D type keg coupler significantly enhances draft quality. It assures an ideal pour, evenly distributing foam and liquid for a exceptional experience. Its effective mechanism maintains steady beer circulation, vital for busy environments and home taverns.

| Feature | Details |

|---|---|

| Client Rating | 4.8/5.0 from 15 reviews |

| Top Reviews | 73% based on 15 reviews |

| Value | $39.99 |

| Shipping | Free on orders over $59 or $8.99 flat rate |

| Heft | 2 pounds |

| Lifetime | Lasts over 6 years according to users |

Frequent Problems and Solutions with Keg Coupler Parts

Regular maintenance and swift problem-solving are key to preventing keg coupler issues that impede beer dispensing. By understanding common malfunctions, you can maintain your draft systems running smoothly. This examination provides strategies for diagnosing issues with keg coupler and recommends substituting parts properly.

Detecting Malfunctions in Keg Couplers

Several problems may affect your keg coupler, resulting in substandard beer dispensing. Frequent faults include leaks due to insecure links or worn rubber washers, accounting for about 25% of observed malfunctions. Furthermore, blocked beer lines, often due to inadequate cleaning, impact roughly 15% of systems.

Using an incorrect coupler type results in about 10% of pouring issues. An additional issue is malfunction of the pressure relief valve in G-Type and U-Type couplers, which influences around 5% of older variants. Identifying these problems early is essential to prevent more serious issues. Consistent monitoring and proper operation are critical for upholding efficient beer service.

Replacing Keg Coupler Parts Efficiently

If you face problems, understanding how to substitute keg coupler parts is vital. For successful replacement, first locating the defective element, like an O-ring or check valve. Then, detach the coupler from the keg by twisting it anticlockwise.

Place a replacement part, ensuring it is a proper match and is suitable. Subsequently, reattach the coupler by pressing down and rotating the handle to the right to secure it. Always inspect for seepage before reconnecting the beer line, confirming a secure seal.

Proper diagnosis of keg couplers not only prolongs your gear longevity but also preserves the excellence of beer dispensed. Sticking to a routine maintenance plan can significantly lessen the chances of defects, thereby enhancing the beer enjoyment.

To Conclude

The D type keg coupler guide is vital for home brewers and tavern owners seeking to enhance their draft beer systems. It aids users in selecting the correct apparatus, guaranteeing the creation of high-quality, tasty beer. D type couplers are widely used all over North America, rendering them indispensable for integrating with major national beer labels such as Budweiser and Miller.

Upkeeping keg couplers is essential for producing fresh, savory beer. This is vital in both commercial and home brewing environments. Regular cleaning stops contamination and is vital for patron contentment in dining venues. Home brewers will find that knowing maintenance practices significantly improves their brewing experience.

Access to premium brewing equipment is essential for top-notch beer serving. Installation Parts Supply is a trusted source for D type keg couplers and maintenance accessories. By opting for the correct equipment and adopting proper maintenance, brewers can greatly enhance their beer delivery performance. Each serving evolves into a more satisfying and triumphant result, elevating the brewing adventure.

Frequently Asked Questions

What are the different types of keg couplers available?

There are various keg couplers, such as the D type (Sankey D), widely used for American kegs. Other versions include the S, G, and A systems. Each is tailored for particular keg styles.

How can I install a D type keg coupler properly?

For setting up a D type keg coupler, first ensure it’s spotless and undamaged. Place it over the keg’s entrance, apply pressure, and turn right until tightly fastened. Then, attach the gas and beer lines, ensuring that all junctions are firm.

How should keg couplers be maintained?

Keg coupler care entails washing after every use and inspecting for drips. Also, quickly substitute worn out parts. Always select trusted vendors for keg coupler parts to maintain functionality.

Why is the D type keg coupler important for draft beer systems?

The D type keg coupler is vital for linking gas and beer lines to a keg. This link is crucial for serving draft beer at its best quality, with perfect carbonation and freshness.

How can I buy a D type keg coupler?

D type keg couplers are sold from several providers, including Installation Parts Supply. They offer a wide selection, ensuring you find the ideal coupler for your demands.

How do I diagnose problems with my keg coupler?

If experiencing issues, initially ensure all connections are firm. For leaks or poor performance, inspect the coupler for defects. Replacing faulty parts often fixes these complications.

Which materials are used for D type keg couplers?

D type keg couplers are primarily crafted from stainless steel. This alloy provides durability, longevity, and safeguarding against corrosion, shielding your beer dispensing system from contamination.

Is a D type keg coupler compatible with other keg types?

No, a D type keg coupler is exclusively for Sankey D kegs. Trying to use it with other keg types can cause substandard junctions and likely leaks.